Mild steel is a kind of metal that isn’t too hard but still strong. It’s used to make tools, machines, and buildings, among other things. Gentle steel is not difficult to shape when it’s warmed, and it doesn’t break without any problem.

Welding stainless to mild steel with flux core? That resembles joining two various types of metal utilizing an extraordinary strategy. It’s like trying to make two identical pieces of a puzzle fit perfectly together. We should find out about the way things are completed.

When welding mild steel to stainless steel with flux core. A special wire known as flux core is melted to join the two metals. The transition center wire fills in as a paste that keeps the gentle steel and treated steel intact. for projects where stainless steel’s strength and mild steel’s flexibility are required. This type of welding is useful.

Welding Stainless to Mild Steel with Flux Core

Envision you have two mates, areas of strength for one intense, the other bendy and adaptable. Welding spotless to gentle steel with a transition center resembles uniting these two pals to make something far superior. Mild steel is like a friend who can bend and change, while stainless steel is like a friend who can stand up to anything.

In the field of metalworking, the ability to weld stainless to mild steel with flux core. It opens up a whole new world of possibilities. Like having a superpower empowers you to build and make things that were believed to be unimaginable. Thus, prepare to set out on a thrilling excursion.

Understanding Stainless Steel and Mild Steel

Stainless steel is like a superhero metal because it is durable and resistant to rust and stains. It can be found in shiny pots, pans, and other kitchen utensils. It is also used by builders in expensive buildings because it looks good for a long time. It’s a piece like the shield knights wear in stories. It safeguards things from getting harmed.

Gentle steel is another intense metal, but it’s not quite as sparkling as treated steel. You can detect it in bunches of regular things, like the casing of a bike or the body of a vehicle. Like your favorite superhero sidekick, it is sturdy and dependable. Both mild steel and stainless steel are strong in their own ways and can be combined.

Overview of Flux Core Welding Stainless to Mild Steel

Motion center welding is a cool method for joining stainless steel and mild steel with flux core. It’s like using a magical wire that melts and binds the two metals strongly. The extraordinary thing about transition center wire is that it has smidgens of stuff inside it. It assists with cleaning the metals as they soften. This means that cleaning the metal before welding doesn’t take as much time.

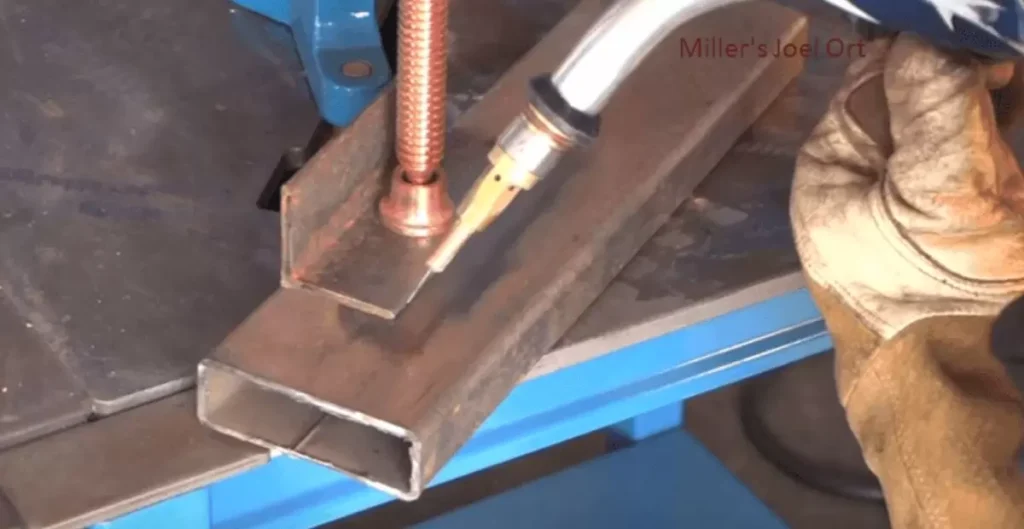

With motion center welding, you can make a wide range of things, similar to walls, vehicle parts, or even figures. It’s like having the ability to build things. The best part is that you don’t need any fancy tools to do it. You are ready to go as long as you have a welding machine and some mild steel with flux core wire. Simply try to wear your wellbeing gear, like a cap and gloves, since welding can get pretty hot.

Benefits and Challenges of Welding Stainless to Mild Steel With Flux Core

Welding hardened steel to mild steel with flux core can be useful in light of the fact. It allows you to make things that are more grounded and more sturdy. By welding two different kinds of metal together, you can make something stronger and able to withstand a lot of use, such as a cool robot or sturdy fence. It opens up more opportunities for making things that are major areas of strength for both adaptable, which is helpful.

In any case, it’s not generally a piece of cake. When welding stainless to mild steel wi, sometimes they won’t stick together. It’s like gluing two pieces of a puzzle that don’t quite fit together. You would have to change the welding settings, clean the surfaces all around well. You attempt various methods to inspire them to weld.

Preparation and Safety Measures

It is essential to prepare and ensure your safety before picking up that welding torch. First things first, make sure you’re wearing the right gear. That implies wearing thick gloves to safeguard your hands from flashes and intensity. A durable welding cap to protect your eyes and face, and an extreme coat to conceal your body. Wellbeing gear is like your hero suit, it protects you while you’re working with hot stuff.

The next step is to prepare the metal. Stainless steel and mild steel may appear clean and shiny. But they may conceal oil and dirt that could contaminate your weld. Thus, give them a decent scouring with a unique cleaner to ensure they’re immaculate. Goodness, and remember to check your welding gear as well from the welding machine to the links.

Choosing the Right Flux Core Wire

Choosing the right flux core wire is super important when welding stainless to mild steel. It is comparable to selecting the appropriate paintbrush for a masterpiece. Different transition center wires are intended for various kinds of metals. Some are designed for mild steel, while others are made for stainless steel. Choose a wire that is compatible with the metals you will be welding.

Thus, before you begin welding, pause for a minute to contemplate your metals and do a little research. Find flux core wires marked for welding mild steel to stainless steel. These wires are made to work best, resulting in clean, strong welds for you. Keep in mind, the right motion center wire can have a significant effect in your welding project.

Techniques for Successful Welding Stainless to Mild Steel

While welding stainless steel to gentle steel with a motion center, certain methodology should be followed to guarantee a smooth cycle. Cleaning the metals is essential prior to beginning the welding process. This involves disposing of any oil, rust, or soil. After that, set up your welding machine by following the on-screen instructions.

Work on practicing your welding skills on scrap metal before starting the actual project. This makes your final weld stronger and helps you get the hang of it. Finally, to ensure even melting and bonding of the metals, keep a steady hand and move the welding torch along the joint at a steady speed. With these procedures, your welding ought to be a triumph.

Common Mistakes to Avoid Welding Stainless to Mild Steel

While welding hardened steel to gentle steel with a motion center. Avoiding common blunders that could compromise the quality of the weld is critical. Neglecting to clean the metals’ surfaces prior to welding is one such error. Soil, oil, and rust can taint the weld, debilitating its solidarity. In this way, it’s fundamental to scour the surfaces clean with a wire brush or a degreaser. It ensures that the metals will stick together well.

Curious about MIG welding stainless steel? Let’s explore. When MIG welding stainless steel, using the correct gas, like argon, is crucial for strong welds. Additionally, improper adjustment of the welding machine’s settings can lead to poor-quality welds. Ensure you follow the manufacturer’s guidelines and adjust settings, like voltage and wire speed, accordingly. Avoiding these errors ensures your welding projects are sturdy and reliable.

Applications and Uses of Welding Stainless to Mild Steel With Flux Core

At the point when we weld treated steel to gentle steel with a motion center. We open ways to a great many applications and utilizations. In the construction industry, this kind of welding is used to build sturdy, long-lasting structures. These designs are scaffolds, structures, and, surprisingly, enormous machines. Engineers can develop structures that can endure strong burdens and cruel atmospheric conditions.

The assembling area benefits from welding gentle steel to treated steel with a transition center. It is used for the production of various tools and machinery. From straightforward hand instruments to complex modern hardware. This welding strategy permits makers to deliver solid and effective items. The ability to weld these two metals together.

FAQs

What types of projects can benefit from welding stainless to mild steel with flux core?

This welding method is valuable for developing solid designs like structures and extensions. As well as assembling instruments and hardware for different businesses.

Is it difficult to learn how to weld stainless steel to mild steel with flux core?

While it requires practice and wellbeing precautionary measures. With appropriate direction and preparation, anybody can figure out how to weld these metals together actually.

Are there any special considerations for safety when performing this type of welding?

To avoid accidents and exposure to harmful fumes. It is essential to wear protective gear, ensure adequate ventilation in the workplace, and adhere to safety procedures.

Conclusion

Think about all the amazing things we can do with this method. We come to the end of our journey into welding mild steel to stainless steel using flux core. The possibilities are endless, and they range from sturdy bridges. They cross great rivers to towering skyscrapers that reach for the stars. It’s not an enormous task to contemplate every one of the regular apparatuses.

But keep in mind that learning how to weld these metals together is more than about making cool things. Safety and responsibility are also at stake. We’ve discussed wearing the right stuff and working in a protected climate. But at the same time it’s tied in with dealing with our devices and rehearsing our abilities.