Welding is when two bits of metal are combined by softening them with intensity. It allows them to cool to shape areas of strength for argon.

Curious about what gas for welding stainless steel? Wondering about the right gas? Let’s discover. When welding stainless steel, the key gas to use is argon. It shields the metal, ensuring strong, clean welds. Learn more about this important gas and how it makes your welding projects sturdy and reliable.

While welding tempered steel, utilizing argon gas is significant in light of the fact. It keeps the metal from responding with oxygen in the air, which could debilitate the weld. Argon makes a safeguard around the welding region. It is clean and guarantees areas of strength for argon between the bits of stainless steel.

Importance of Choosing the Right Gas

At the point when we discuss welding hardened steel. Need to pick the right gas. It’s like making a sandwich, if you wanted a ham sandwich, you wouldn’t use chocolate spread. The gas we select for welding functions to an exclusive component. It ensures flawless welding. In the event that we pick some unacceptable one.

Envision fabricating a cool LEGO spaceship. Assuming you use some unacceptable pieces, it won’t remain together, and parts could tumble off. In welding, on the off chance that we don’t use the right gas. Our metal pieces won’t stay together as expected, and the weld could be frail. The right gas behaves like a superhuman safeguard, shielding our metal from hurt during the welding experience.

Understanding the Properties of Stainless Steel

A special kind of metal called stainless steel doesn’t rust as other metals like iron do. This is on the grounds that it contains a blend of metals, like chromium and nickel. This makes it impervious to rust and consumption. You can find stainless steel in heaps of spots, like kitchen sinks, utensils, and in enormous designs like scaffolds and structures. Its solidarity and strength settle on it a famous decision for things.

One more cool thing about tempered steel is that it’s gleaming and looks pleasant. It’s solid, but it likewise adds a smooth and present day touch to anything that it’s utilized for. On account of its protection from rust. Its attractive features, stainless steel, are utilized in a wide range of things. Those ordinary things are water containers to favor things like gems and watches.

Role of Gas in Welding Process

When we weld metal, it’s like cooking something hot. We use an oven mitt to protect our hands, we need something to protect the metal. That’s where gas steps in! It forms a special shield around the metal while it’s hot. This shield keeps out all the bad stuff, like oxygen and other gasses in the air, that can hurt the metal.

Suppose we attempted to fabricate something with powerless metal. It would be like building a sandcastle that self-destructs when the tide comes in. That is the reason gas is so significant in welding. It helps ensure our welds are areas of strength. We give our metal a superhero shield when we use gas. It holds the metal protected back from getting injured and ensures our welds keep intact all around well.

Overview of Different Gasses Used in Welding

Suppose we attempted to fabricate something with powerless metal. It would be like building a sandcastle that self-destructs when the tide comes in. That is the reason gas is so significant in welding. It helps ensure our welds are areas of strength.

We give our metal a superhero shield when we use gas. It holds the metal protected back from getting injured and ensures our welds keep intact all around well. Whenever we are welding, we must always ensure that we have the appropriate gas. It safeguards our metal and produces the highest quality welds possible.

Advantages of Using Argon for Welding Stainless Steel

Using argon gas for welding treated steel enjoys various benefits. Argon, right off the bat, makes a defensive safeguard around the welding region. It keeps oxygen and different pollutants from defiling the metal. This safeguard keeps up with the tidiness of the hardened steel. It decreases the gamble of rust and guarantees serious areas of strength for argon bonds. Argon gives steadiness during the welding system.

Also, argon is inert, which means that it does not react chemically with the stainless steel. As a result, the material retains its original properties, ensuring it doesn’t undergo any unintended changes in composition. Just like using the right grit sandpaper for a smooth finish, the use of argon gas in welding stainless steel offers unwavering quality, neatness, and control. This results in superior welds suitable for various applications.

Practical Tips for Welding Stainless Steel with Argon

Gear Arrangement: Before beginning, guarantee your welding gear is set up. Check the gas stream rate and change it as prescribed by the hardware maker. It guaranteed the consistent and suitable progression of argon gas during welding.

Neatness Matters: Keep your welding region spotless and liberated from soil, residue, and oil. Before welding, ensure that the surface of the stainless steel is cleaned. Because contaminants can weaken the weld and reduce its quality.

Right Method: Use the right welding method for hardened steel. Keep a consistent hand and steady development to make even areas of strength for and. Work on controlling the welding light and changing your speed to do ideal outcomes.

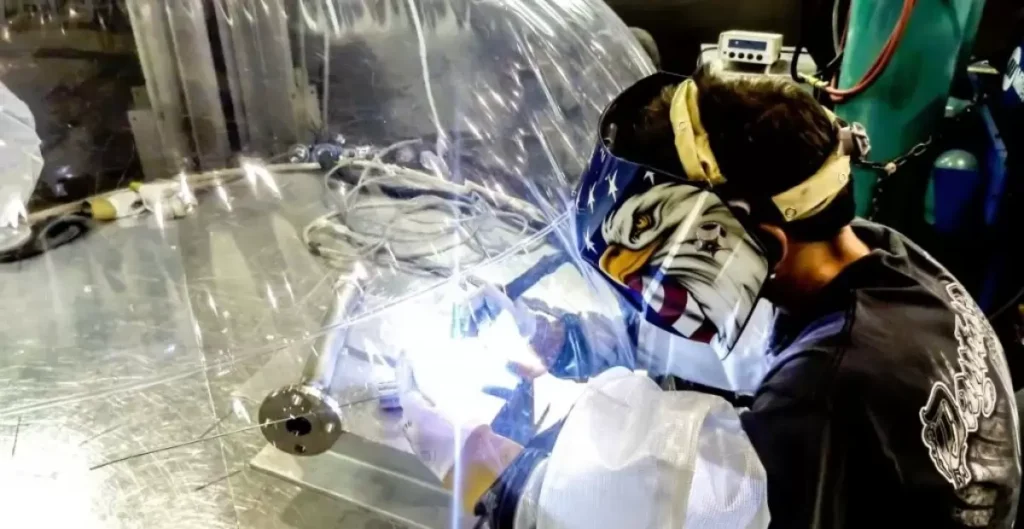

Security First: Focus on security while welding. Wear suitable defensive stuff like welding gloves. A welding cap with a legitimate shade focal point, and defensive dress to safeguard yourself from flashes, intensity, and UV light produced during welding.

Argon Protection: Comprehend the significance of argon gas in safeguarding the welding region from air foreign substances. Guarantee that the argon gas inclusion is enough to make a defensive safeguard around the weld zone, forestalling oxidation and guaranteeing clean welds.

Joint Planning: Appropriately set up the joints before welding. Slant or chamfer the edges of the stainless steel pieces. It guaranteed appropriate infiltration and combination during welding, particularly for thicker materials.

The practice of perfection: Be encouraged by introductory difficulties. You can hone your skills and gain confidence in handling the welding equipment. This is honed by practicing welding on scrap stainless steel pieces.

Screen Welding Boundaries: Watch out for welding boundaries like voltage, amperage, and travel speed. It keeps up with consistency and quality all through the welding system. Make changes as important to upgrade weld entrance and appearance.

Post-Weld Examination: After finishing the weld, assess it. If this is conceivable, use non-damaging testing strategies to guarantee. It fulfills quality guidelines. Search for indications of deformities like breaks, porosity, or deficient combinations and address them .

Look for Direction: If you encounter difficulties or have questions about welding stainless steel with argon gas. Don’t be afraid to ask instructors or experienced welders for help. Gaining from others’ encounters can assist with working on your abilities. Keep away from normal traps.

Safety Considerations During Welding Process

While you’re welding, security is significant in light of the fact that you’re managing hot stuff.

- You are dressed appropriately. That implies a strong cap to shield your eyes and face from flashes zooming around, and gloves to protect your hands from the intensity. Gracious, and remember about wearing long sleeves and jeans to conceal your skin. You need no consumes, believe me.

- Regarding your workspace, it must be organized. You need no messiness or stuff lying around that could burst into flames from those hot flashes. Also, keep anything that could catch fire far away from your welding area.

- We should discuss the gas you’re utilizing, like argon. It’s not something worth talking about to mess with. You have to be cautious while dealing with it. Since it tends to be hazardous in the event that you don’t have the foggiest idea what you’re doing. Ensure you’re adhering to every one of the directions on the most proficient method to use it.

- Gracious, and another thing, never weld alone. Continuously have somebody close by who can take care of you on the off chance that something turns out badly. Being protected than sorry, right?

Common Mistakes to Avoid When Welding Stainless Steel

To ensure strong and long-lasting welds when welding stainless steel. It’s important to avoid these common blunders.

- Before welding, the metal must be cleaned. Any soil, oil, or buildup on a superficial level can taint the weld and debilitate its solidarity.

- Second, excessive heat can cause the stainless steel to warp or sag, lowering the quality of the weld as a whole.

- Utilizing some unacceptable gas, for example, not utilizing argon when important. It can bring about unfortunate weld entrance and lack of protection, prompting second rate weld quality.

- By staying away from these missteps and avoiding potential risk. You can do top notch welds while working with treated steel.

FAQs

What are some common mistakes to avoid when welding stainless steel?

While welding treated steel, it’s vital to keep away from specific missteps like not cleaning the metal. It can use extreme intensity, and not utilizing the suitable gas, like argon.

Why is cleaning the metal before welding important?

Cleaning the metal before welding eliminates soil, oil, and buildup. That can pollute the weld, guaranteeing more grounded and more dependable welds.

What role does the right gas play in welding stainless steel?

Using the right gas, like argon, is essential in welding stainless steel. As it gives legitimate safeguarding to forestall pollution and guarantees top notch welds.

Conclusion

So, when you’re all done with your welding of stainless steel, make sure to remember these important things. First, always clean the metal well before starting. This keeps it free from any dirt or yucky stuff that could mess up your weld. Second, be careful with how much heat you use. Too much use of heat can make the metal bend in weird ways.

And, don’t forget to use the right gas, like argon. It helps keep everything quite clean while you’re welding. So your work turns areas of strength out tough. You will be able to create fantastic welds if you keep these suggestions in mind.